E-Waste Shredder Machine

Price 550000 INR/ Unit

E-Waste Shredder Machine Specification

- Size

- 2400 x 1200 x 1800 mm

- Motor Power

- 22 kW

- Weight

- 1850 kg

- Control System

- PLC Controlled

- Thickness

- Up to 10 mm

- Color

- Green & Black

- Sheet Capacity

- Depends on E-Waste Size

- Processing Type

- Double Shaft Shredding

- Voltage

- 415 V

- Capacity

- 500-1500 kg/h

- Application

- E-waste, PCB Boards, Electronic Devices Shredding

- Noise Level

- Low (<80 dB)

- Frequency

- 50 Hz

- Material

- MS (Mild Steel)

- Automatic Grade

- Automatic

E-Waste Shredder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

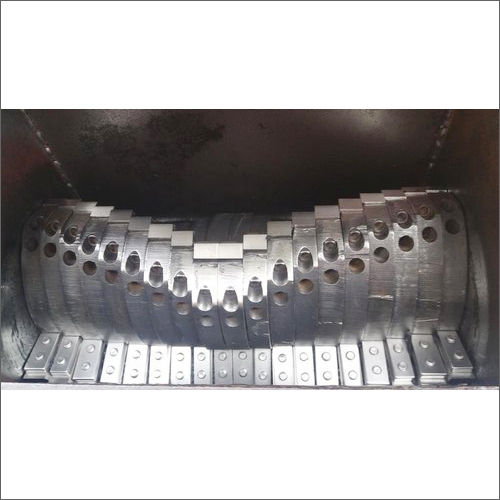

About E-Waste Shredder Machine

With the support of our diligent team of professionals, our organization is able to manufacture and supply an assorted range of the E-Waste Shredder Machine. It is extensively used to completely destroy any kind of information stored in hard drives, tablets, phones or other devices. The offered range is made by using the top grade quality materials and ultra-modern techniques, as per the industry standards and norms. Furthermore, you can avail the offer of the E-Waste Shredder Machine in various specifications and at pocket-friendly prices.

Efficient E-Waste Recycling Solution

Designed to streamline electronic waste management, this shredder efficiently reduces the volume of e-waste, PCB boards, and discarded electronics. Its double shaft shredding action and automatic feeding via conveyor belt expedite processing, making it a reliable choice for recycling centers and waste processors seeking significant throughput.

Advanced Safety and Smart Control

User safety and operational reliability are prioritized with features such as an emergency stop button and overload protection. The PLC-controlled system ensures precise, automated operation, while the air-cooled system maintains optimal machine temperatures to prevent overheating during continuous use.

Mobility and Durability Combined

Constructed from heavy-duty mild steel and equipped with castor wheels, this machine offers both durability and easy mobility. Its substantial weight and stable frame enable thorough shredding with reduced vibration, while low noise emissions create a safer, more comfortable working environment.

FAQs of E-Waste Shredder Machine:

Q: How does the conveyor belt feeding system enhance the shredding process?

A: The conveyor belt automates feeding of e-waste, ensuring a consistent and controlled flow into the shredding chamber. This increases efficiency, reduces manual handling, and enables steady processing for higher throughput.Q: What types of materials and electronic devices can this shredder handle?

A: This shredder is designed for e-waste, PCB boards, and various electronic devices, capable of processing items up to 10 mm thickness thanks to its durable 24 alloy steel blades and 600 x 500 mm chamber.Q: When is air cooling preferred in shredding operations?

A: Air cooling is ideal during prolonged operations, as it maintains the machines temperature without the complexity of liquid cooling systems, ensuring safe and continuous shredding even in warmer environments.Q: Where can this E-Waste Shredder be deployed?

A: Its movable design with castor wheels allows deployment in a variety of locations, including recycling facilities, electronic waste collection centers, and industrial plants across India.Q: What benefits does the PLC-controlled system offer?

A: A PLC control system streamlines operations by automating shredding sequences, monitoring machine parameters, and swiftly responding to faults, enhancing safety, user convenience, and consistent shredding performance.Q: How does the machine ensure user safety during operation?

A: It is equipped with an emergency stop button for immediate shutdown and overload protection to prevent mechanical damage or electrical hazards, prioritizing operator safety at all times.Q: What is the typical processing capacity of this shredder?

A: Depending on the size and type of e-waste, the machine offers a high processing capacity ranging from 500 to 1500 kg per hour, making it suitable for medium to large-scale recycling operations.

More Products in Waste Shredder Machine Category

Industrial Waste Shredder Machine

Price 475000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Processing Type : Shredding

Voltage : 415 V

Automatic Grade : Automatic

Medical Waste Shredder Machine

Price 2000 INR / Piece

Minimum Order Quantity : 1 Unit

Control System : PLC Based Control Panel

Processing Type : Shredding

Voltage : 415 V

Automatic Grade : Automatic

Electrical Waste Shredder Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Based

Processing Type : Shredding

Voltage : 415 V

Automatic Grade : Automatic

Plastic Waste Shredder Machine

Price 435000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Processing Type : Shredding

Voltage : 380 V

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS