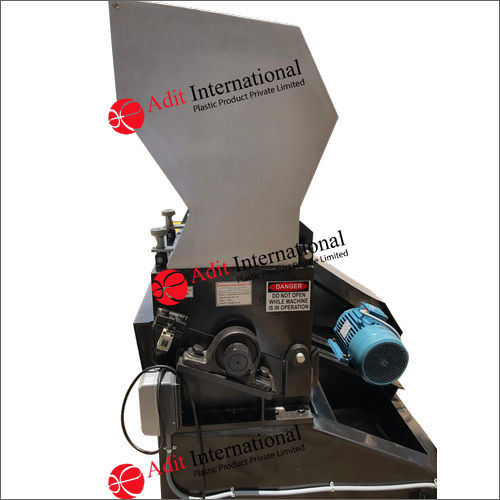

Automatic PET Bottle Shredder Machine

Price 240000 INR/ Unit

MOQ : 1 Unit

Automatic PET Bottle Shredder Machine Specification

- Control System

- Microprocessor based with user-friendly interface

- Size

- Approx. 1200 mm (L) x 800 mm (W) x 1450 mm (H)

- Thickness

- Up to 2 mm bottle walls

- Sheet Capacity

- Multiple PET bottles per pass

- Application

- PET bottle recycling, Waste management, Industrial and commercial use

- Weight

- Approx. 280 kg

- Voltage

- 220-240 V

- Color

- Blue / White / Custom

- Automatic Grade

- Automatic

- Processing Type

- Shredding / Crushing

- Material

- Mild Steel (Body) / Hardened Steel (Blades)

- Frequency

- 50-60 Hz

- Motor Power

- 2 HP

- Noise Level

- <70 dB

- Capacity

- 100-150 kg/hr

Automatic PET Bottle Shredder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Automatic PET Bottle Shredder Machine

Specification

- Voltage: 230 V

- Country of Origin: Made in India

- I Deal In: New Only

- Crushing Chamber Size: 24 Inches

- Is It Corrosion Resistant: Corrosion Resistant

- Material: Mild Steel

- Size: 7 feet x 7 feet x 5 feet

- Weight: 1 Ton

- Warranty: Life Time Warranty (Unbreakable Industry First )

- Driven Type: Electric Motor

- Frequency: 50 Hz

- Power: 20 HP

- Blade Size: 24 Inches

- Model Name/Number: ADIT - ADT 100

- Dimension: 18 Inch Cutting Area

- Plastic Type: PET, PP,NYLON, PVC, HDPE,LDPE,PC,NYLON,etc

- Type: Automatic

- Machine Type: Automatic

- Power Consumption: 20 HP

- Capacity: 250 Kg per hour

- Usage/Application: Grinding Plastics or shredding plastics

Efficient and Versatile Shredding

Engineered to handle PET, plastic, and similar synthetic bottles, this machine shreds various bottle types up to 2 mm wall thickness. Its large shredding chamber and high-capacity motor allow simultaneous processing of multiple bottles, generating uniform 10-20 mm flakes suitable for recycling. The combination of rotary and fixed alloy steel blades ensures consistent performance and a long operational lifespan.

User-Friendly and Safe Operation

Equipped with a microprocessor-based control system, the shredder offers intuitive operation and precise management. An array of safety features-including emergency stop, overload protection, and safety interlocks-promotes operator security. Manual feeding and hopper-fed options provide flexibility based on workflow needs. The machine remains easy to move and maintain, ensuring minimal downtime and straightforward cleaning.

Built for Industrial Reliability

Manufactured from durable mild steel with hardened steel blades, the machine is suitable for demanding environments such as recycling plants, waste management facilities, and commercial spaces. Its robust build, energy efficiency, and quiet operation make it a dependable solution for continuous use within a temperature range of 0C to 45C. Customizable color options and compact footprint further enhance its adaptability.

FAQ's of Automatic PET Bottle Shredder Machine:

Q: How does the Automatic PET Bottle Shredder Machine operate?

A: The machine operates automatically using a microprocessor-based control system, with options for manual or hopper-fed bottle feeding. Once bottles are placed into the chamber, rotary and fixed alloy steel blades shred them into 10-20 mm flakes for easy recycling.Q: What types and sizes of bottles can the shredder process?

A: It is designed to handle PET, plastic, and similar synthetic bottles with wall thicknesses of up to 2 mm. Multiple bottles can be fed at once, optimizing throughput and efficiency.Q: When is maintenance required, and how is it performed?

A: Maintenance is recommended regularly, depending on usage levels. The machine features easy-access maintenance panels, allowing quick cleaning and servicing of blades and chamber to ensure sustained performance.Q: Where can the shredder be installed and used?

A: This machine is ideal for recycling plants, waste management centers, and commercial or industrial settings across India. Its fitted wheels make it easy to relocate within facilities as needed.Q: What safety features are included to protect users?

A: Safety is prioritized with overload protection, an emergency stop switch, and safety interlocks to prevent unscheduled access or operation, ensuring safe and reliable use in busy working environments.Q: How does the discharge system work after shredding bottles?

A: Shredded bottle flakes are collected via a chute or bin collector for convenient disposal or further processing, keeping the workspace clean and organized.Q: What are the primary benefits of using this shredder for PET bottle recycling?

A: Key advantages include high-capacity processing, energy efficiency, mobility, low noise, and a robust build, making the machine a cost-effective and reliable choice for industrial waste management and recycling operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PET Bottle Shredder Machine Category

Industrial PET Bottle Shredder Machine

Price 240000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Color : Blue & White

Automatic Grade : Automatic

Sheet Capacity : 3540 Bottles/Cycle

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS